Across industries, the move toward sustainability is no longer optional — it’s essential. .

Data Centers & Water: Turning Cooling Tower Blowdown Into a Strategic Resource

As AI adoption accelerates, data centers have become the physical backbone of the digital world, powering everything from virtual assistants to predictive analytics and generative models. Behind every compute cycle, however, lies a critical resource that rarely makes the headlines: water.

Large data centers depend on water to manage the enormous heat generated by high-density servers. For a 100-megawatt facility, that can mean up to 2 million liters of water per day, roughly the daily use of thousands of households. At the same time, many of the regions attracting hyperscale development are already under water stress. Balancing growth in computing capacity with responsible water use is becoming a defining challenge for the industry.

This is where a smarter strategy for cooling tower blowdown (CTBD) can make all the difference. Instead of disposing of CTBD as a waste stream, operators can instead treat it to transform into a reliable internal source of high-quality recycled water.

The Hidden Water Footprint of Data Centers

Most conversations about data centers focus on power usage effectiveness (PUE). Yet water plays an equally critical role in keeping infrastructure online.

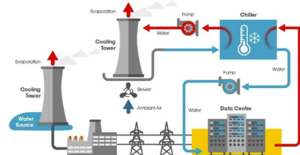

Servers and networking devices run constantly and generate enormous amounts of heat. Without effective heat dissipation, they overheat and fail. While air-based systems are widely used, water-based cooling is often far more efficient at managing the massive thermal loads produced by modern, high-density hardware, especially for AI and other intensive workloads.

Water is used to control humidity, to support chillers, in adjacent power plants that supply electricity to the data center, and during system maintenance and testing of backup systems. Everything is interconnected, and all of it depends on a stable, well-managed water supply infrastructure.

The result is a substantial and continuous demand on local water resources, often drawn from municipal potable systems because they are the most accessible. In water-stressed regions, this can put data centers in direct competition with communities, agriculture, and other industries for the same limited supplies. At the same time, environmental regulations increasingly restrict how heated and concentrated waste streams can be discharged back into rivers, lakes, or coastal waters.

Typical Data Center Water Infrastructure

To maintain their license to operate, data centers must show that they are using water more efficiently, recycling wherever possible, and minimizing their freshwater footprint. What makes this challenge more acute is that it is not static. The scale, intensity, and geographic footprint of data centers are changing rapidly, and with them, the demands placed on local water infrastructure.

Water as a Strategic Constraint: What’s Changing by 2026

Looking ahead, water is poised to become one of the defining constraints on data center growth. As artificial intelligence workloads proliferate and compute density rises, water demand is accelerating faster than many regional water systems were designed to accommodate. Industry analyses increasingly point to the mid-2020s as a turning point, when water availability, treatment capacity, and regulatory scrutiny will directly influence where data centers can be built and how they can operate.

1. Water Demand Will Grow Sharply with AI Infrastructure Expansion

Data centers are inherently water-intensive due to cooling needs, especially for facilities hosting AI training and inference workloads. Large facilities can consume millions of gallons per day, with some estimates projecting a significant increase in water requirements as AI demand accelerates.

For example:

- Typical data centers already use hundreds of thousands to millions of gallons of water daily for cooling operations.

- Broader projections indicate that as facility capacity rises, water use associated with cooling operations could grow by several multiples compared with current baselines.

This trend means water demand across the sector could intensify by 2026 and beyond, driven by both new builds and increased compute density per facility.

2. Water Availability Will Influence Siting Decisions

Water supply and regulatory frameworks are already emerging as location determinants for new data center projects. Data centers built in arid or water-stressed regions — such as parts of the U.S. Southwest, the Middle East, and parts of Asia — may compete directly with municipal and agricultural users for dwindling resources.

Key implications include:

- Governments and utilities increasingly scrutinizing water permits and allocations for high-consumption facilities.

- Companies facing higher compliance risk in basins with tight supply or during drought periods.

- Some municipalities considering moratoriums or regulatory caps on new centers until water strategies are formalized.

Operators are responding by factoring water security and sustainability into early site assessments and by prioritizing sources that reduce freshwater withdrawal.

3. Recycling and Alternative Water Strategies Are Becoming Essential

Water reuse, closed-loop cooling, and advanced treatment technologies are no longer optional add-ons — they are trending toward baseline requirements for long-term viability. Several leaders in the industry are investing in water-efficient system designs that recirculate or reuse cooling water, significantly lowering net consumption.

Circular and recycled water strategies not only reduce dependency on local freshwater but also cushion data centers against regulatory and community pushback in stressed basins.

4. Innovation Is Focused on Water Efficiency and New Cooling Approaches

Traditional evaporative cooling systems — which lose water through evaporation as part of heat rejection — are under scrutiny both for water use and environmental impact. New approaches emerging in the industry include:

- Hybrid or dry cooling techniques that significantly lower water use.

- Closed-loop systems that minimize external withdrawals.

- More granular water performance metrics (e.g., Water Usage Effectiveness, WUE) that help benchmark and manage water performance at scale.

Together, these trends point to a clear conclusion: securing long-term water resilience will require more than incremental efficiency gains. Data centers will need to treat water as a managed resource within the facility boundary, recovering, recycling, and reusing it wherever possible to reduce dependence on external supplies and discharge pathways.

Why Cooling Tower Blowdown Is the Best Place to Start

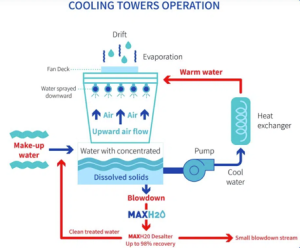

In this context, cooling tower blowdown represents one of the most practical and impactful starting points for improving a data center’s water balance. In a typical evaporative cooling system, water circulates through cooling towers, absorbs heat, and is partially lost as vapor. As evaporation occurs, dissolved salts and minerals concentrate in the remaining water. To keep scaling and corrosion under control, operators periodically purge part of the circulating water. That purge is the cooling tower blowdown.

CTBD is an ideal target for recycling:

- It is already collected at a single point in the facility.

- Flow and composition are relatively consistent.

- It carries a significant fraction of the facility’s dissolved solids load.

If CTBD can be treated and reused as make-up water, the data center can reduce its dependence on external freshwater sources, cut discharge volumes and associated costs, and increase its cooling tower cycles of concentration—all without changing the core cooling concept.

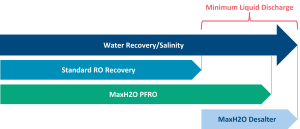

The technical barrier is water chemistry. CTBD is typically a brackish stream enriched with sparingly soluble salts such as silica, calcium carbonate, and calcium sulfate. Conventional brackish water RO (BWRO) systems are often limited to 75–80% recovery before scaling becomes unmanageable. Pushing recovery higher with traditional designs usually requires additional stages, booster pumps, and recirculation loops, making the system more complex and expensive.

Designing High-Recovery CTBD Systems: From Chemistry Limits to Practical Solutions

Cooling tower blowdown (CTBD) is one of the most attractive targets for water reuse in data centers—but it is also one of the most technically constrained. As dissolved salts concentrate through evaporation, sparingly soluble compounds such as silica, calcium carbonate, and calcium sulfate quickly reach scaling thresholds. Conventional brackish water reverse osmosis (BWRO) systems typically plateau at 75–80% recovery, beyond which scaling risk, chemical consumption, and operational instability increase sharply.

Achieving higher recovery requires a different design philosophy—one that separates salt removal from osmotic pressure limits and manages scaling chemistry proactively rather than defensively.

A System-Level Approach to High Recovery

In practice, high-recovery CTBD reuse systems must address three challenges simultaneously:

- Prevent scale formation on membrane surfaces while operating at elevated recoveries

- Remove problematic salts from the system instead of endlessly recirculating them

- Minimize concentrate volume early, reducing downstream disposal or ZLD complexity

This calls for an integrated approach that combines membrane separation with controlled salt precipitation and advanced membrane operation, allowing recovery to increase without pushing the system into unstable operating regimes.

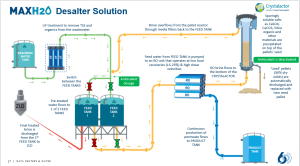

IDE applies this logic through its MAXH₂O solution architecture, which was developed specifically for high-salinity, scale-prone industrial streams such as cooling tower blowdown. Rather than relying on increasingly complex multi-stage RO layouts or aggressive chemical dosing, the approach focuses on managing chemistry at the system level.

MAX H2O Value Proposition

Removing Scaling Salts as Solids, Not Sludge

One of the core principles behind MAXH₂O is the controlled removal of sparingly soluble salts as dense solids rather than allowing them to accumulate in solution. In a typical configuration, CTBD is treated using reverse osmosis operated at a conservative local recovery, safely below scaling limits. The permeate produced at this stage is already suitable for reuse as high-quality cooling tower make-up water.

Instead of sending the resulting concentrate directly to disposal or further RO stages, it is routed to a fluidized bed reactor where scaling inhibitors are intentionally deactivated. Under these controlled conditions, silica, calcium carbonate, and other problematic salts precipitate onto seed material, forming compact pellets. These pellets are periodically withdrawn and handled as a solid waste stream.

By removing sparingly soluble salts from the system in this way, the remaining brine becomes primarily a sodium chloride solution. This allows the process to operate in a closed loop at very high overall recovery, while avoiding the formation of sludge, minimizing fouling risk, and improving hydraulic stability throughout the system.

For data center operators, this translates into higher cooling tower cycles of concentration, reduced freshwater intake, and a substantial reduction in blowdown volumes—all without introducing fragile or chemically intensive treatment steps.

Rethinking RO Operation at High Recovery

In parallel with salt precipitation, IDE also applies a dynamic mode of RO operation designed to push recovery higher within a single membrane stage. Instead of continuous crossflow with a steady concentrate bleed, this approach alternates between short production periods and brief, high-velocity flushing events.

These rapid cycles prevent prolonged salt buildup at the membrane surface, keeping the system within the induction phase of crystallization—where supersaturation exists but crystals have not yet formed. The result is stable operation at recoveries well beyond what is typically achievable with conventional RO designs, while also extending intervals between chemical cleaning.

This dynamic operation reduces system complexity, eliminates the need for multiple RO stages and interstage boosting, and improves overall reliability—key considerations for mission-critical facilities such as data centers.

From Concept to Practice: A High-Recovery Case

The impact of this high-recovery approach is best illustrated through real-world applications..

In this case, an industrial site blended several challenging streams: blowdown from 20 hybrid cooling towers, brine from an existing RO system, and wastewater from manufacturing processes. The existing treatment scheme, ultrafiltration followed by RO, provided make-up water, but it faced persistent problems:

- Silica concentrations of 65–150 mg/L limited RO recovery.

- Cooling towers were constrained to 2–2.5 cycles of concentration, forcing high blowdown rates and large disposal volumes.

- The economics of a ZLD system were unattractive due to the high flow of concentrate.

IDE implemented a MAXH₂O Brine Desalter to treat a portion of the most challenging stream. Operating at around 95% recovery, the Desalter reduced silica in the permeate to about 1 mg/L. When this permeate was blended back into the make-up system:

- Cooling tower cycles of concentration increased from 2 to 4.

- Overall make-up water demand fell by roughly one-third.

- The volume of concentrate was reduced enough to make a compact ZLD system practical, eliminating continuous brine discharge and leaving only dry solids for disposal.

For a data center, a similar configuration would translate into lower freshwater withdrawals, smaller thermal equipment (if needed), and a stronger business case for ambitious water-stewardship targets.

Turning Blowdown into a Strategic Asset

As water availability becomes a defining constraint on data center growth, CTBD recycling offers one of the most immediate and impactful opportunities to improve water efficiency. When designed correctly, high-recovery treatment systems transform blowdown from a waste stream into a reliable internal resource, supporting both operational resilience and long-term water stewardship goals.

Rather than treating water reuse as a compliance exercise, data centers that invest in robust, chemistry-aware CTBD solutions position themselves to scale sustainably in an increasingly water-constrained world.

Contact a water expert today and find out more about how IDE can help you solve your water challenges.